Polyurethane

Injection molder

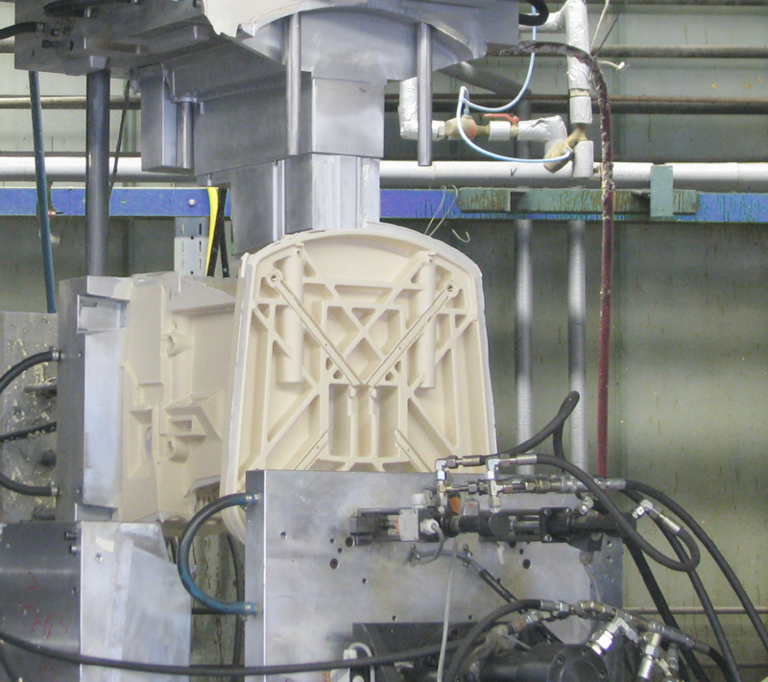

Injection molders are the manufacturers of molded parts, housings and functional parts made of thermoplastics.

The injection molding process allows the fast and cost-efficient production of simple to highly complex parts in only one process step.

Rework is not usual. Injection molders are usually only active when high quantities are produced for mass products as injection molds are expensive.

Typical injection molding parts are e.g. buckets, bottle crates, housing for TVs and radios, kitchen appliances, electric tools as well as mass products in the automobile area.

Thieme produces plastic parts with the RRIM PUR process. Due to close cooperation with network partners, manufacturing in injection molding as well as other molding processes are possible. With Thieme, there is the ability to select the best-suited production method for each part. With our central in-house painting facility, uniform and top-quality surfaces can be achieved. Sub assembly of the individual parts and accessories for a complete part system can also be executed by Thieme. Ask us – we are pleased to supply you with our extensive Injection molding knowledge, experience and information.

GET IN CONTACT WITH US

Let us determine your requirements in an expert discussion.