PUR compact foam

RIM Materials

PUR compact foam

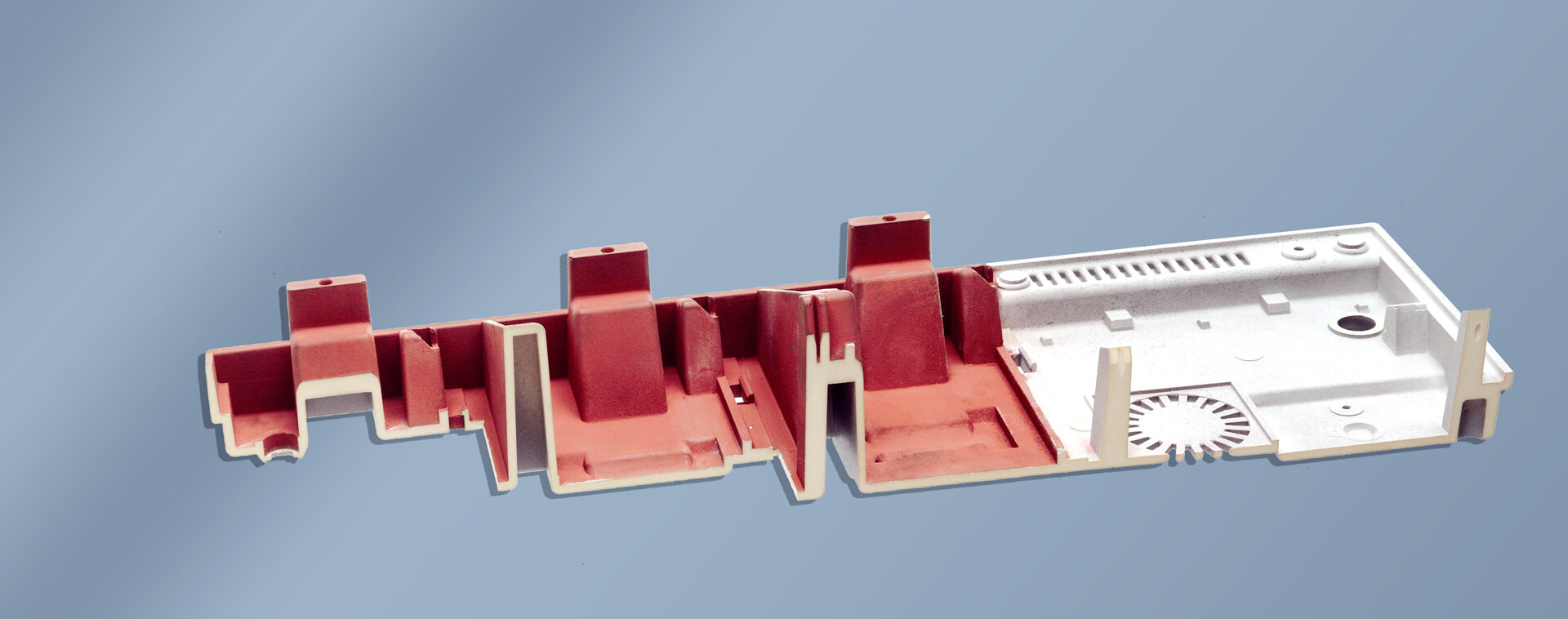

Why compact foam (K110)?

- Compact structure and high impact strength

- Alternative to injection moulding

- Large format components up to 6 m² projected area

- Thin wall sections possible

Fields of application

- Machine and device enclosures

- Medical device application

- Transport and storage containers

- Railway industry

- Heavy equipment and construction machines

- Logistics (Containers and trays)

- Consumer electronics

Technical Data

| Properties | Unit | Standard | K110 |

|---|---|---|---|

| Density | kg/m³ | ISO/R 1183 / DIN 53479 | 1050 |

| Pulling strength | MPa | ISO/R 527 / DIN 53455 | 50 |

| Ultimate elongation | % | ISO/R 527 / DIN 53455 | 14 |

| Bending stress at 3.5 % outer fiber strain |

MPa | ISO 178 / DIN 53452 | 58 |

| Bending E-module | MPa | DIN 53457 | 1900 |

| Impact strength at 23 °C | kJ/m² | ISO/R 179 / DIN 53453 | 57 |

| Surface hardness | Shore D | 75-77 | |

| Dimensional stability (HDT) | °C | ISO 75-2 | 92 |

Values not absolute some may be altered.