Special machine construction - printing technology

Perfectly tailored to your requirements

Printing Systems

Special machine construction

Special machines - optimised for your printing processes

Thieme develops and constructs special machines and special machinery solutions that are specifically made for our customers’ printing needs and preferences.

These are innovative custom-designed printing solutions that meet high technical standards in plant engineering, special machine construction and industrial automation for 24/7 production – from the initial planning phase to implementation and final delivery.

Special machine for digital printing

Four digital printing units, each one for the separate application of primer and colour on the front and back

Pneumatic handling systems (e.g.turning unit)

Integrated robot for support, centering, transport and removal

Rotary table printing system

Printing of molded metal parts

Rotary indexing table with loading and unloading handling

Paper intermediate pressure

Vision technology with inline scanner

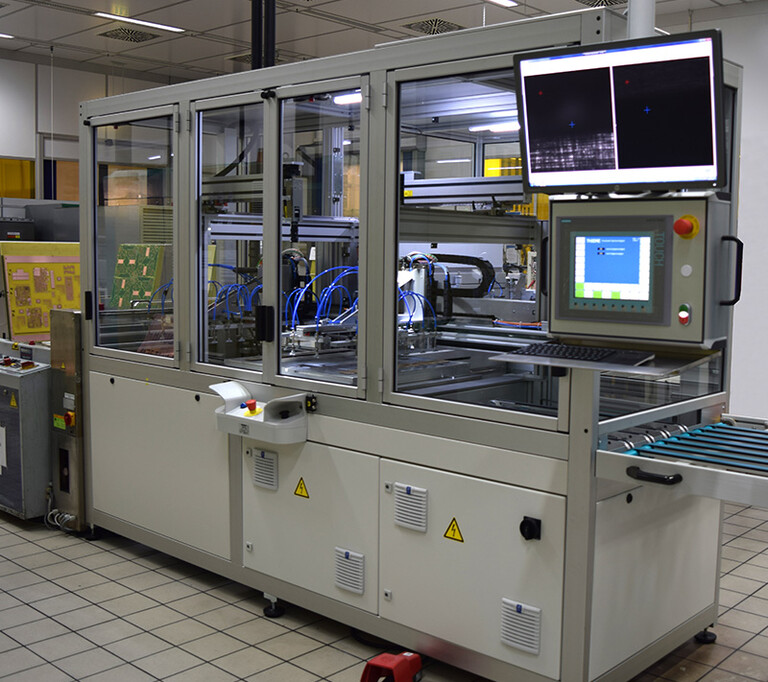

Special machine for electronic printing

THIEME LAB 1000 with attached handling unit

Print size 600 x 600 mm

Handling with 2 axis with vacuum suction cups for loading and unloading

Interfaces for loader / cleaner

Fully automatic screen printing machine with encapsulated housing that reduces dust ingress

Largest screen-printing machine for glass application

THIEME 3000 GS/LS

Print size 7500 x 3300 mm

Max. Screen size 9900 x 4800 mm

Screen frame profile 240 x 80 mm

Possibility of smaller glass formats min. 500 x 250 mm

Printing of foils in a roll-to-roll process

Roll width: min. 305 mm max. 1250 mm

Roll core diameter 3 and 6 Zoll

Roll weight max. 250 kg

Dry with UV option

Possibility to squeeegee horizontally or diagonally

Foils 100 µm - 300 µm

As a Thieme customer, you will receive a full-service experience. Our people provide expert assistance during design, development and manufacturing; all the way to installation and commissioning – and remain available afterwards for service and maintenance. Thieme has expertise in mechanical engineering, PLC programming, control and drive systems, electrical assembly and similar fields. As a developer of special printing machines, we can help you find a machine solution that is tailor-made for your needs. We serve customers in sectors such as manufacturing, automotive, medical equipment and consumer goods.

- Support for development departments and research institutions

- Platform of many different machine types for print tests

- Extensive expertise in screen and digital printing technology

Your benefits

- Design freedom based on proven standards

- Years of experience gained from a wide range of machine installations

- Reliable project execution by highly experienced and knowledgeable employees

- One-stop shop → consulting, project planning, design + development, production + assembly, electrical installation, integration + commissioning, service/customer support, remote access to the machine control system, after-sales services

- Independent, financially stable, family owned mid-size company

- Handiness – we respond swiftly to give you more planning options

- Process transparency and traceability

- Multi-industry knowledge of special machine construction obtained through years of doing business in many different industries

- Design, development and production of special machines and automation units, tailored to your exact budget, requirements and performance and quality specifications

- Full range of state-of-the-art automation technologies (control and drive systems, robotics, industrial image processing)

- Industry 4.0-compliant

- Optional expansion or integration (system integration) of the printing system into new or existing manufacturing lines.

We can draw on our extensive experience and deep expertise in printing, mechanics, electronics, robotics, software development and control systems to craft the very best solutions for your unique requirements.

Depending on your specific needs, we can combine machinery developed in-house with available automation systems – such as rotary index tables, industrial robots, feeding systems, conveying equipment, laser and image processing systems – and integrate them into innovative machine solutions that perform complex tasks and processes.