Polyurethane (PUR) foams are durable, high-performance materials – robust, resistant, and versatile. As a manufacturer of PUR foam parts, we at Thieme are aware that this performance comes with responsibility – especially with regard to the environment and resource conservation.

Sustainability and recycling at THIEME

Taking responsibility. Shaping the future.

Polyurethane (PUR) foams are durable, high-performance materials – robust, resistant, and versatile. As a manufacturer of PUR foam parts, we at Thieme are aware that this performance comes with responsibility – especially with regard to the environment and resource conservation.

The challenge: Due to their cross-linked structure and high durability, PUR foams are particularly long-lasting – this is a great advantage in use, but it also poses special challenges for recycling. But this is exactly where we come in: Together with leading material manufacturers and research partners, we are continuously working on innovative solutions to recycle PUR materials as efficiently and sustainably as possible.

Recycling process for PUR foams

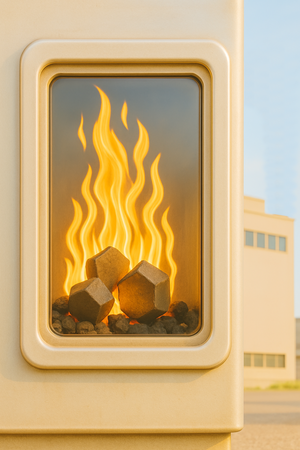

Thermal recycling

When PUR foams can no longer be recycled at the end of their life cycle, thermal recycling offers a sensible and ecologically sound option:

Polyurethane has a high energy content and is therefore valued as a valuable substitute fuel in modern waste incineration plants. The stored energy is recovered in the form of heat or electricity and fed into the energy system. This energetic use makes an important contribution to the efficient use of resources – especially when mechanical or chemical recycling is not possible or economically viable.

Mechanical recycling

In mechanical recycling, PUR residues are shredded and then mixed with binders or fresh PUR. Heat and pressure are used to create new molded parts – regardless of whether the foam is hard or soft.

Thieme has already tested this process in practice and gained experience with various material combinations. The results show that mechanical recycling is a resource-saving and economically attractive solution – especially for production waste and single-type returns.

Chemical recycling

In this process—e.g., glycolysis, hydrolysis, or acidolysis—PUR foams are broken down into their raw materials (such as polyols). These can then be used to manufacture new PUR products. Although this process requires more energy, it opens up promising prospects for a truly circular economy in the long term.

Thieme is actively involved in the further development of mechanical and chemical recycling processes – in close cooperation with material manufacturers and scientific partners.

The path to a bio-based future

At Thieme, we are increasingly integrating such sustainable raw materials into our production – with the aim of minimizing environmental impact, conserving resources, and at the same time ensuring the highest quality and durability of our PUR foam parts.

The last 3 blog entries

Innovativ und dekorativ: PUR mit Oberfläche kombiniert – ein altbewährtes Paar für neuste Anwendungen

Sep 6, 2023

Read article

Salt Spreader Container made from PUR

Apr 4, 2023

Read article

6 Applications of Reaction Injection Molding (RIM)

Sep 27, 2023

Read article