Efficient product tracking in the global supply chain mosaic: from press monitoring to customised print production. Companies recognise the key role of tracking for competitive advantage and customer satisfaction.

Product Tracking in the Printing Process: From Machine Monitoring to Personalized Print Production

In today's globalized world, where products arrive from various locations around the globe, product tracking and traceability play an increasingly vital role. Companies have recognized that efficient management of their supply chain is crucial to gaining competitive advantages and enhancing customer satisfaction.

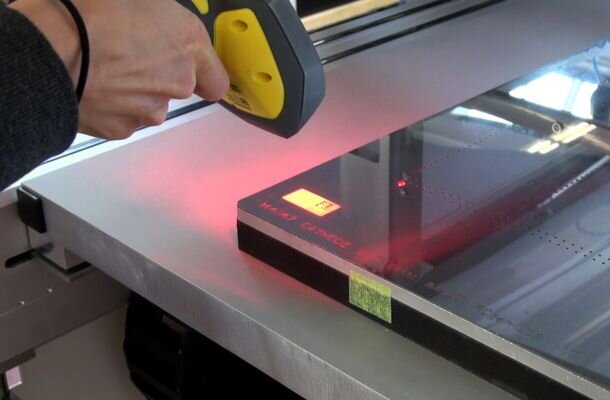

Product tracking refers to the process of monitoring products throughout the entire supply chain, from manufacturing to delivery to the end customer. By utilizing various technologies such as:

- Data Matrix Codes (DMC)

- QR Codes

companies can monitor the location, status, and other relevant information of their products in real-time.

Revolution in Product Tracking: Diverse Solutions and Variants for Optimal Tracking

Fundamentally, we have developed multiple solutions with different variants for product tracking. However, each customer receives their own tailored tracking solution.

The following modules serve as the foundation for the variants and are customized to meet customer requirements.

"BASIC" Product Tracking for Process Monitoring

In our Basic version, tracking is used for machine monitoring and maintenance. It allows our customers to monitor the condition and performance of printing machines in real-time, enabling early detection of maintenance needs and minimizing unplanned downtime.

Monitoring printing machines and predictive maintenance through product tracking offer customers a range of benefits:

- Optimization of machine availability

- Predictive Maintenance

- Extension of equipment lifespan

- Reduction of downtime

- Lower maintenance costs

- Enhancement of overall production process efficiency

"COMFORT" Product Tracking for Quality Control

Product tracking and traceability play a critical role in product quality control. It enables customers to trace the origin and path of a product through the supply chain, storing details such as

- production date

- production time

- recipe values

In the event of quality issues or recalls, traceability allows customers to quickly and accurately identify affected components and take appropriate actions.

"ADVANCED" Product Tracking with Interaction

By integrating tracking features, the printing machine can "quasi" communicate with the customer system, providing data-driven decisions. Each part reports data to the customer system and receives a message from the customer system regarding whether the part should be rejected, further processed, or printed before printing.

For instance, a customer request was setup control:

Comparing the item to be printed with the order

- Does the blade match the order?

- Does the screen match the order?

- Does the foil match the order?

- Does the foil match the print stage?

Using Advanced Product Tracking, our customers can customize their products to meet the individual needs and preferences of their customers. This allows for personalized or individualized prints with a batch size of 1.

The Challenge - Ensuring Print Quality and Consistency

In such cases, product tracking can be a valuable application

Product tracking refers to the monitoring and recording of information about a specific product during the manufacturing process. It enables us to store detailed data about the parameters and settings required for the production of your high-quality end product.

In the case of screen printing, various recipe values such as

- Paste

- Squeegee pressure

- Flood and squeegee speed

- Settling times

- Application point screen lift and lift height

- Screen printing forme distance

stored directly in the screen layout. This information serves as a reference for future print orders, ensuring that each print is identical and of high quality.

Especially in demanding print orders such as printing with silver pastes, product tracking is of great importance. Silver printing requires precise settings and optimal conditions to achieve a "functional result." Silver is used to print conductive traces for items such as airbag sensors, seat heating, switches. The challenge is that the thin printed lines must not cause a short circuit. By using product tracking, manufacturers can document the specific parameters required for successful silver printing and replicate them when needed.

Overall, product tracking plays a significant role as an application aid in:

- Ensuring quality standards

- An audit (required by automotive manufacturers, possibly)

- Efficient use of materials

- Production efficiency

You already have a THIEME printing machine?

Retrofitting product tracking is an option

Product tracking can also be retrofitted to existing machines and adapted to your existing ERP system.

App-based solutions are possible for

- remote access

- or SMS notification for problems

Conclusion!

Product tracking refers to the process of monitoring products throughout the entire supply chain, from manufacturing to delivery to the end customer. By utilizing various technologies such as barcodes and QR codes, companies can monitor the location, status, and other relevant information of their products in real-time.

We offer 3 modules (BASIC, COMFORT, and ADVANCED) for product tracking, which serve as a foundation and are customized for each customer.

#ProduktTracking #MachineMonitoring #PersonalizedPrintProduction

The last 3 blog entries

Leading with technology – and colour

Jul 4, 2023

Read article

Combined expertise in a dynamic duo

Aug 16, 2023

Read article

Boundless creativity in Screen Printing

Jun 12, 2023

Read article