The Thieme Print Engine enables the integration of single- and multi-pass inkjet printing systems into existing production lines. Fast, flexible, modular, and easy to maintain.

THIEME Print Engine

Integration of inkjet printing technologies into existing production facilities. The Thieme Print Engine combines speed, precision, and flexibility. Whether single-pass for high speed or multi-pass for maximum resolution, we deliver the optimal solution for your production.

- Single- & multi-pass systems – speed and flexibility in one portfolio

- Can be used inline or offline – integration or stand-alone

- Flexibility in ink selection

- Ink supply adapted to your ink system

- Standard equipment with Ricoh print heads, other print heads available on customer request

- Adaptation to your transport system

- Short setup times, consistent quality

- Scalable and modular for future requirements

- Integration of pre- and post-processes possible

- Plasma corona pretreatment

- Cleaning systems such as brush cleaning, adhesive roller, vacuum cleaning

- Other customer-specific processes

Your advantages with the THIEME Print Engine

Take your production to the next level with the Thieme Print Engine. Our systems combine high production speed with the highest print quality and can be flexibly adapted to your requirements.

- Single-pass for high speed & series production

- Multi-pass for high resolution, flexibility & customization

- Personalization and print on demand

- Easy to maintain & durable

- Resource-saving operation

- Technology that makes your production smarter

Technology that makes your production smarter

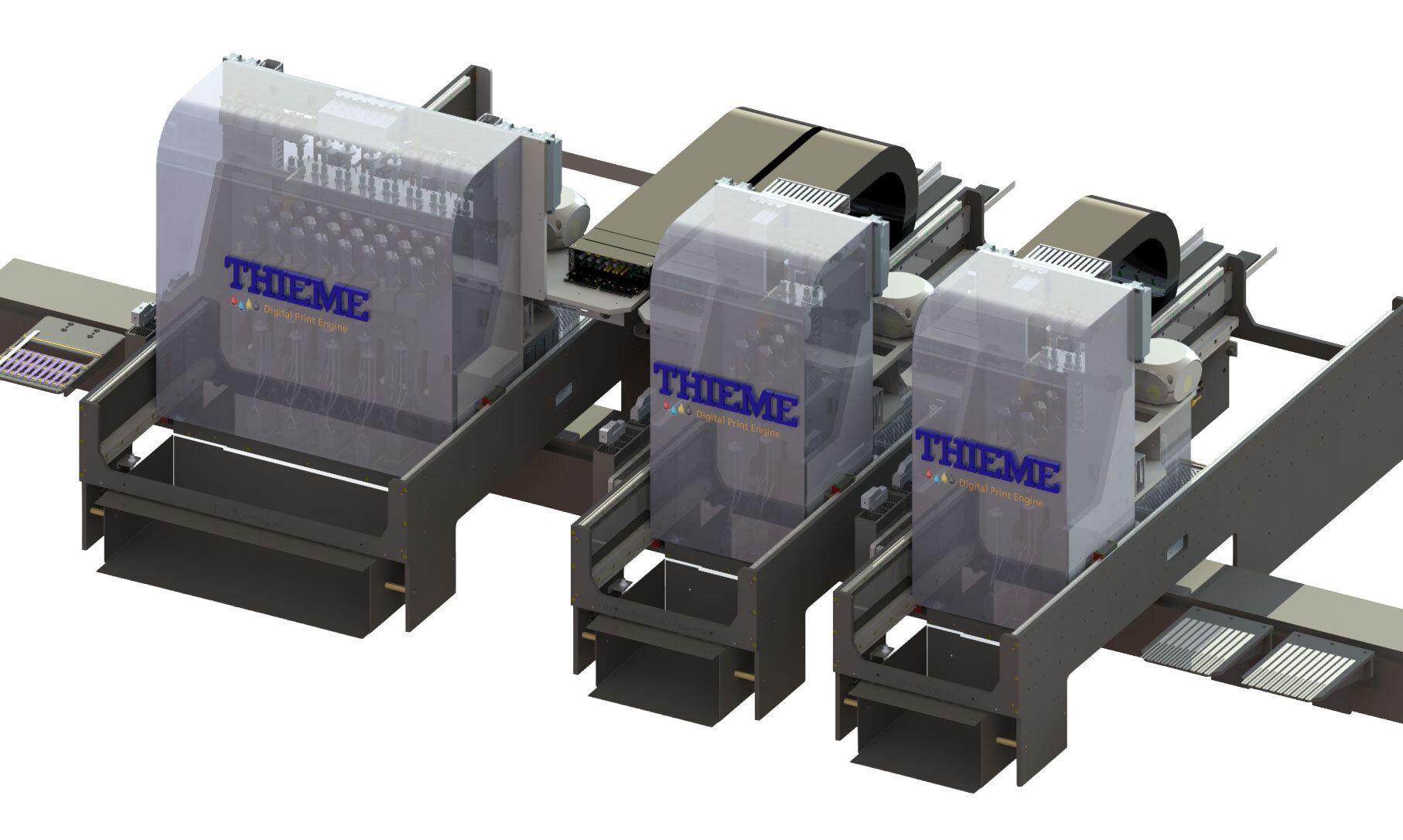

Our print engine combines state-of-the-art print head technology with intelligent software and hardware integration. Thanks to its modular architecture, your system can be expanded at any time – for new processes, colors, or curing systems.

- Precision print head device with easy replacement

- Automated cleaning and maintenance functions (purge, cleaning, wiping)

- Integrated pre/post processes such as cleaning units, QR code markers/scanners

- Modular system – retrofittable, expandable, future-proof

- Easy operation via intuitive HMI (multilingual, role-based, remote support possible)

- Inline & offline application

- Easy to integrate – efficient production

Easy integration – efficient production

The Thieme Print Engine can be seamlessly integrated into existing production lines or used as a stand-alone system. Thanks to our scalable widths and flexible modules, we can find the optimal solution for your production environment.

Thieme developers and assembly personnel provide support for mechanical and control integration. Thieme application engineering provides support for process integration.

- Automotive: functional coatings, markings

- Electronics: circuit boards, insulation, protective coatings

- Glass, plastic, metal: decorative & functional printing

- Medical technology: precise, reproducible markings

- Packaging: variable data, coding, branding

- Shorter setup times, higher machine availability

- Combination of mass production & customization

- Sustainable use of resources

- No major modifications necessary

- From consulting to production – everything from a single source

From consulting to production – everything from a single source

Services:

- Consulting & analysis – evaluation of processes, costs, funding opportunities

- Project planning & concept – planning, components, layout

- Implementation & commissioning – design, prototyping, integration, training

- Maintenance & support – service contracts, spare parts, remote support, production support

Start your integration project now

With the Thieme Print Engine, you get a solution that combines speed, quality, and future-proofing. Let's work together to optimize your production processes.

The last 3 blog entries

When technology touches – and comes to life on coins

Aug 12, 2025

Read article

Adhesive printing in digital printing

Apr 18, 2024

Read article

Why our digital printing machines are unbeatable in industrial digital printing!

Jun 30, 2023

Read article