THIEME 3000 Vision AL

Latest screen printing machine generation

specifically designed for film, sheet metal, and electronics applications

screen printing series

THIEME 3000 Vision AL (AutoLoader)

Latest screen printing machine generation

specifically designed for film, sheet metal, and electronics applications

Why THIEME ?

- Thieme Quality „Made in Germany“

- Individually configured and manufactured according to customer requirements

- Over 60 years of experience in screen printing and automation

- Over 10,000 installed machines

- Long life expectancy of a Thieme machine (over 20 years)

- Global service

- Process support during production start-up optionally available

- Network with leading ink, screen, and substrate manufacturers

- Testing and development possibilities at the Thieme Technology Center

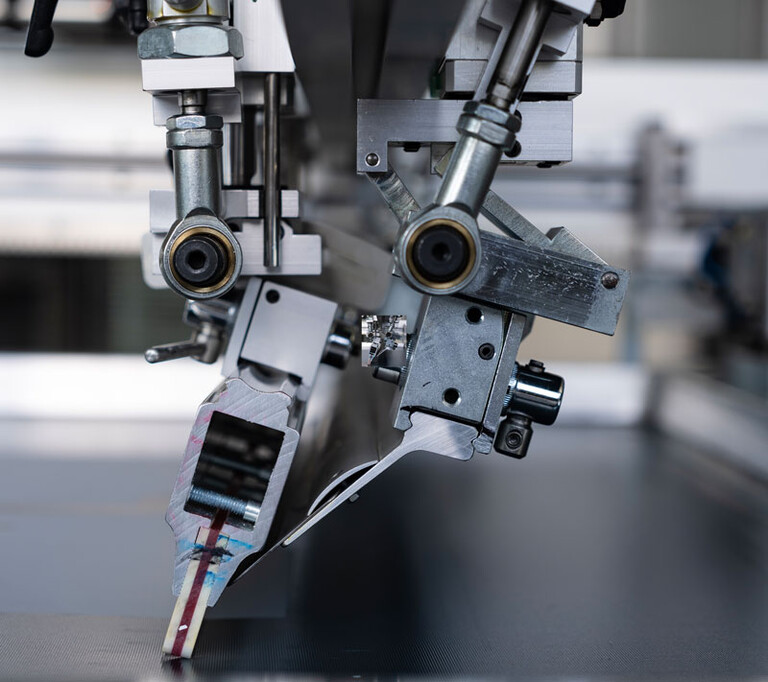

Specifics

- Highest precision through camera-assisted substrate alignment

- Material-friendly transport due to pick & place handling

- System enables processing of films below 100μm

- Also suitable for rigid materials

- Proven Thieme Vision System for screen and substrate alignment

- Optional Advanced Print Control (APC) for setup time optimization

- Customizable with extensive machine options

- Intuitive machine operation

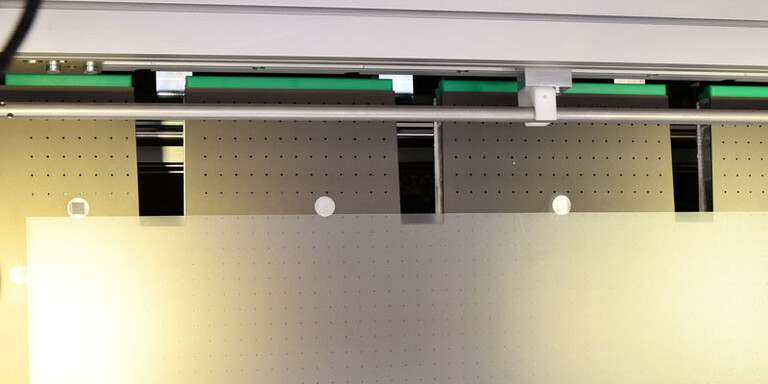

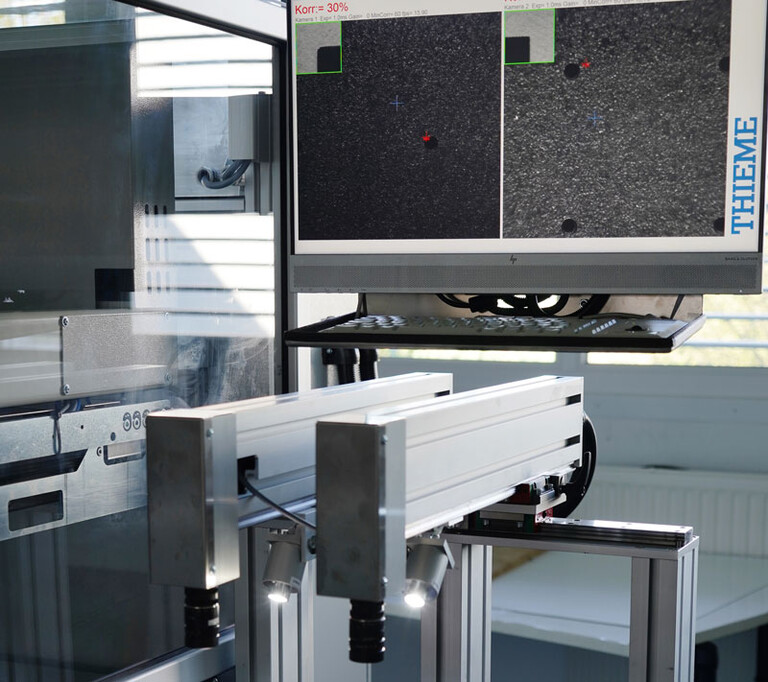

THIEME Vision-System

The THIEME 3000 Vision AL comes standard with the THIEME Vision-System.

THIEME Vision - Screen positioning

The days of manual adjustment of screen position belong to the past. Set up your Thieme screen printing machine in less time and gain valuable production time. The Thieme Vision screen positioning system works with an very high accuracy, minimizing set up prints.

- Automatic Setup

- Reduce set-up times

- High-precision screen alignment

- Minimum make ready prints

THIEME Vision - Substratate positioning

Reduction of set up prints and an improvement in accuracy?

Increase your productivity and quality. The Thieme Vision system allows a new level of quality.

- High-precision printing-material alignment

- Reduction of make ready prints

- Eliminates placement errors

- High reproducibility

| Screen positioning | |

|---|---|

| Number of cameras | 2 / expandable |

| Mechanical repeatability [μm] | + / - 40 |

| Alignment mark [mm] | round, white, ø3 |

| Screen adjustment | motorized |

| Substrate positioning | |

|---|---|

| Number of cameras | 2 / expandable |

| Mechanical repeatability [μm] | + / - 30 |

| Alignment mark [mm] | flexible |

| Table alignment | servomotor, air, bearing |

Technical Data

| Type of machine | 3010 | 3020 | 3030 | |

|---|---|---|---|---|

| Print size [mm] | 550 x 750 | 750 x 1050 | 1000 x 1400 | |

| Sheet size max. [mm] | 580 x 780 | 780 x 1080 | 1030 x 1420 | |

| Sheet size min. [mm] | 300 x 200 landscape | |||

| Frame size[mm] | 1180 x 1380 | 1380 x 1680 | 1630 x 2020 | |

| Screen rest at max. format [mm] | 300 | |||

| Printing table | 800 x 1050 | 1000 x 1350 | 1250 x 1700 | |

| Vacuum field size [mm] | 565 x 756 | 765 x 1065 | 1015 x 1405 | |

| Substrate thickness max. [mm] | up to 16 | |||

| Substrate thickness*1 min. [mm] | 50 μm | |||

| Screen adjustment [m/sec] | + / - 6 | |||

| Alignment accuracy [mm] | + / - 50 μm bei cmk 1,67; absolute + / - 30 μm | |||

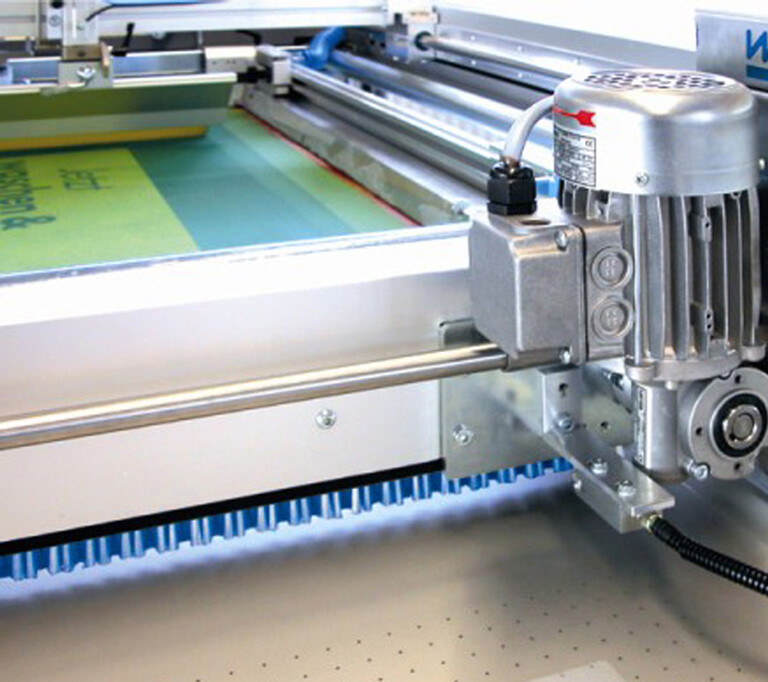

| Squeegee speed [m/sec] | 0,1 - 1,4 | |||

| Weight [kg] | 2300 | 2600 | 2900 | |

| Print speed*2 [cycl/h] | 420 | 400 | 390 | |

| Power supply [V] | 400 | |||

| Power supply [kW] | 4,2 | |||

| Power supply [A] | 6 | |||

| Material feeding | Right / Left / Center | |||

| Position Camera marks Table orientation |

Complete sheet area freely selectable | |||

| Position Camera marks Screen direction |

Position selectable by arrangement | |||

| Print direction | 90° to the transport direction | |||

| Max. Stacking height [mm] | 500 | |||

| Max. Stacking weight [kg] | 1000 | |||

All technical information is not binding and subject to change.

|

||||

Customized innovative machine options

APC

Advanced-Print-Control

- Detection & correction of register deviations during setup

- Cyclic checking / readjustment

Anti-Drip

- Anti-drip for printing and/or flood squeegees

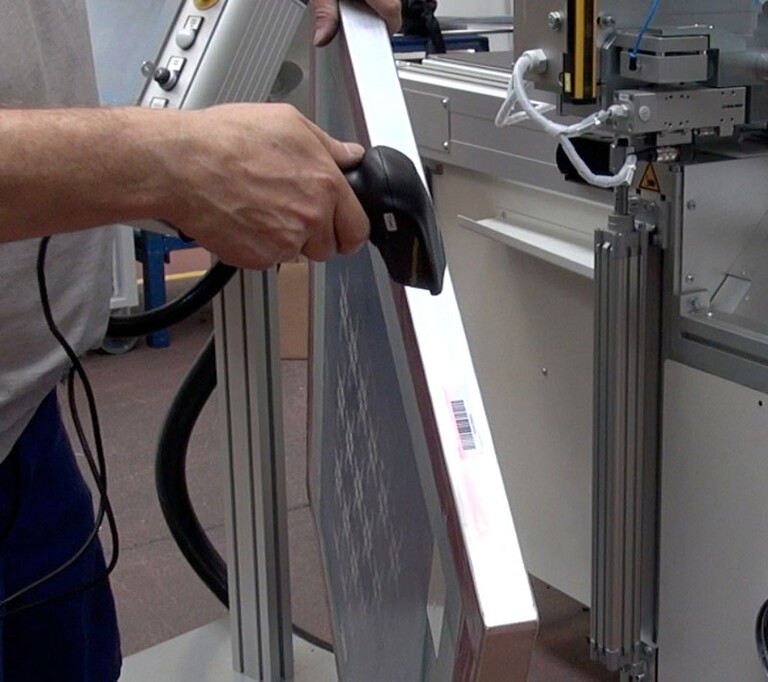

Barcode Handscanner

- For documentation of material batches (film, paint)

- To call the print program

Integrated Barcodesystem

- Barcode imprint on first print

- Documentation (traceability)

Screen stretch compensation

- Effects of screen stretch compensation can be minimized

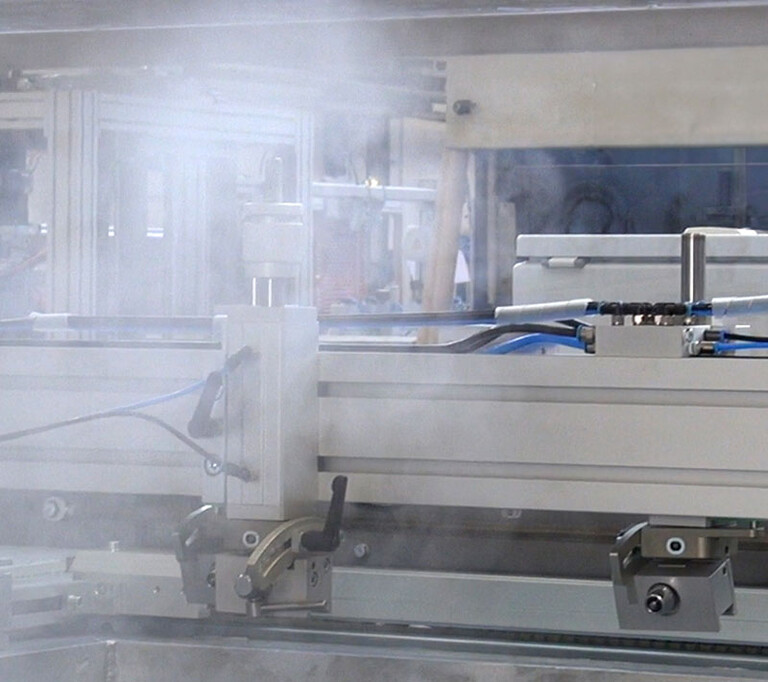

Humidity control

- Automatically humidify the printing environment

- Reduces drying of the screen

Screen clean

- Automatic screen humidification (screen clean)

- Removes dried paint without manual cleaning

Process air dosing

- Filtered

Intermediate paper

printing

Screen pull-out system

- Screen cleaning outside the printing station

Integrated substrate

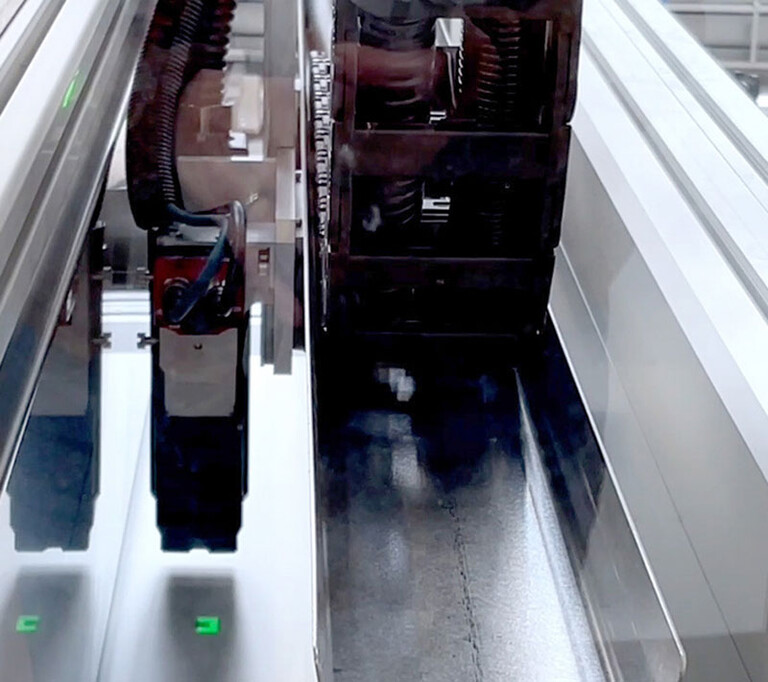

cleaning

- Automatic foil cleaning before printing

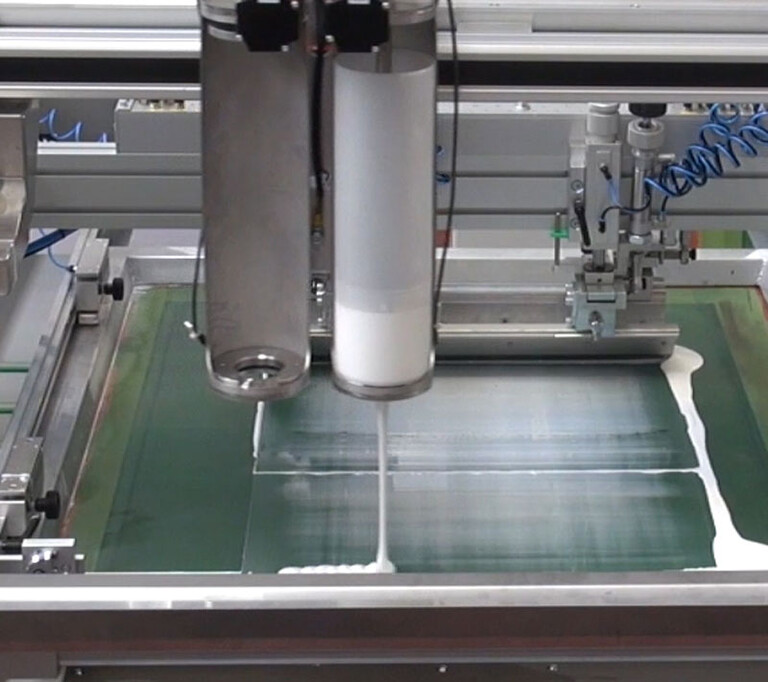

Paste dosing

- Pastes are supplied cyclically

Applications

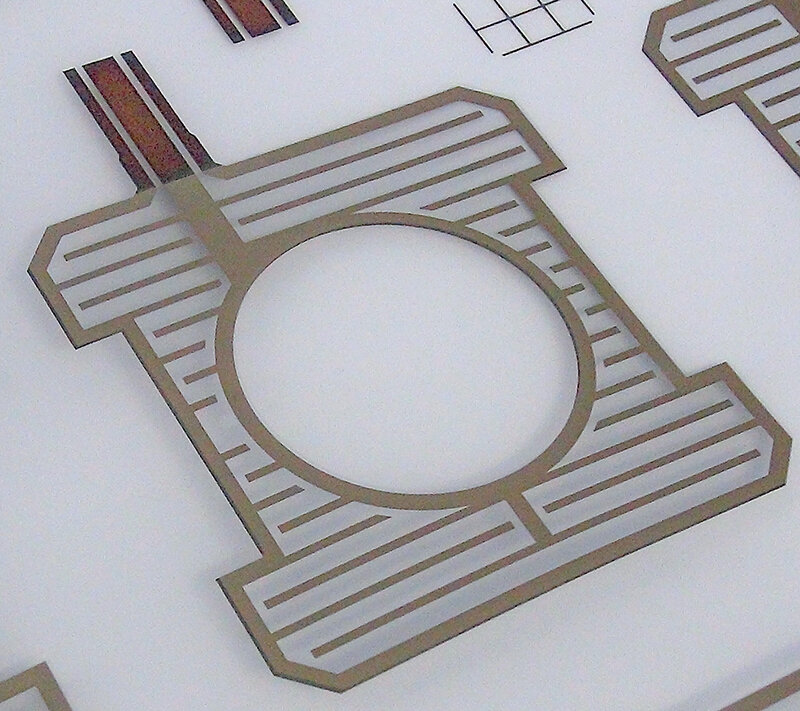

The application opportunities of functional printing processes know no bounds and something new is being added every day: for example, the production of antennas, membrane keypads or strip conductors.

More ...

We support our customers in the development of new processes by providing process entry solutions ("Lab-to-Fab"), which we test in our own Technology Center. We also perform feasibility studies.

Are you seeking solutions for the production of fuel cells, thin-layer solar cells (CIGS, DSSC, etc.), batteries or the like? Thieme designs its customized print line in close collaboration with its customers.

More ...

Machines are built for roll-to-roll, thin layer on glass, and even for high-precision screen printing applications.

The decorative printing of front foils and keyboard membranes for the production of flat input systems always require a customised design. The Thieme screen printing and digital printing solutions leave nothing to be desired.

More ...

(In-Mold Labeling / Film Insert Molding)

Thieme's industrial digital printing system offers new possibilities for coloured and decorated injection-moulded parts. It meets the same requirements in terms of durability, adhesion or formability as apply in screen printing. The digital printing system's particular benefits comprise improved reproduction of colour gradients and the display of fine writing. Its high flexibility enables a more cost-effective small batch production.

More ...