Polyurethane

Structural Foam

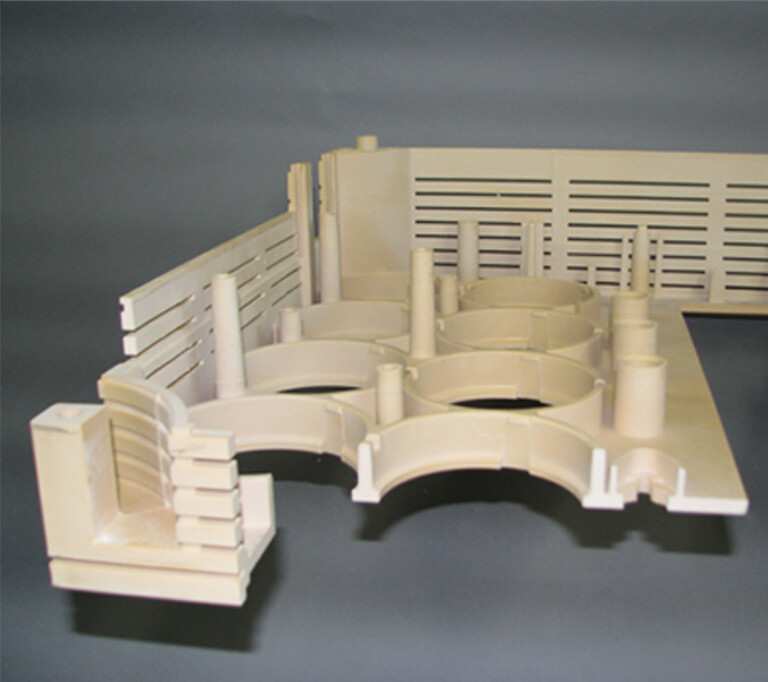

In the structural foam process, thermoplastic foam injection, a blowing agent is mixed with the thermo plastic pellets in low concentration or is pumped into the melt in the barrel in a fluid state under high pressure. This addition of the blowing agent causes a foam core in the part. Hence, wall thickness difference or large sink marks and deformation can be avoided. Weight reduction can also be achieved. This technology is well suited to durable large format parts that require strength and rigidity.

The structural foam process is used for molded parts which should have wall thickness differences but cannot be designed otherwise. For the structural foam process injection molding machines can be used.

An alternative process to structural foam is the processing of PUR foams which achieve the same properties through a chemical reaction of the raw materials.

Thieme produces plastic parts with the RRIM PUR process. Due to close cooperation with network partners, manufacturing in structural foam as well as other molding processes are possible. With Thieme, there is the ability to select the best-suited production method for each part. With our central in-house painting facility, uniform and top-quality surfaces can be achieved. Sub assembly of the individual parts and accessories for a complete part system can also be executed by Thieme. Ask us – we are pleased to supply you with our extensive structural foam knowledge, experience and information.