THIEME 1000 E

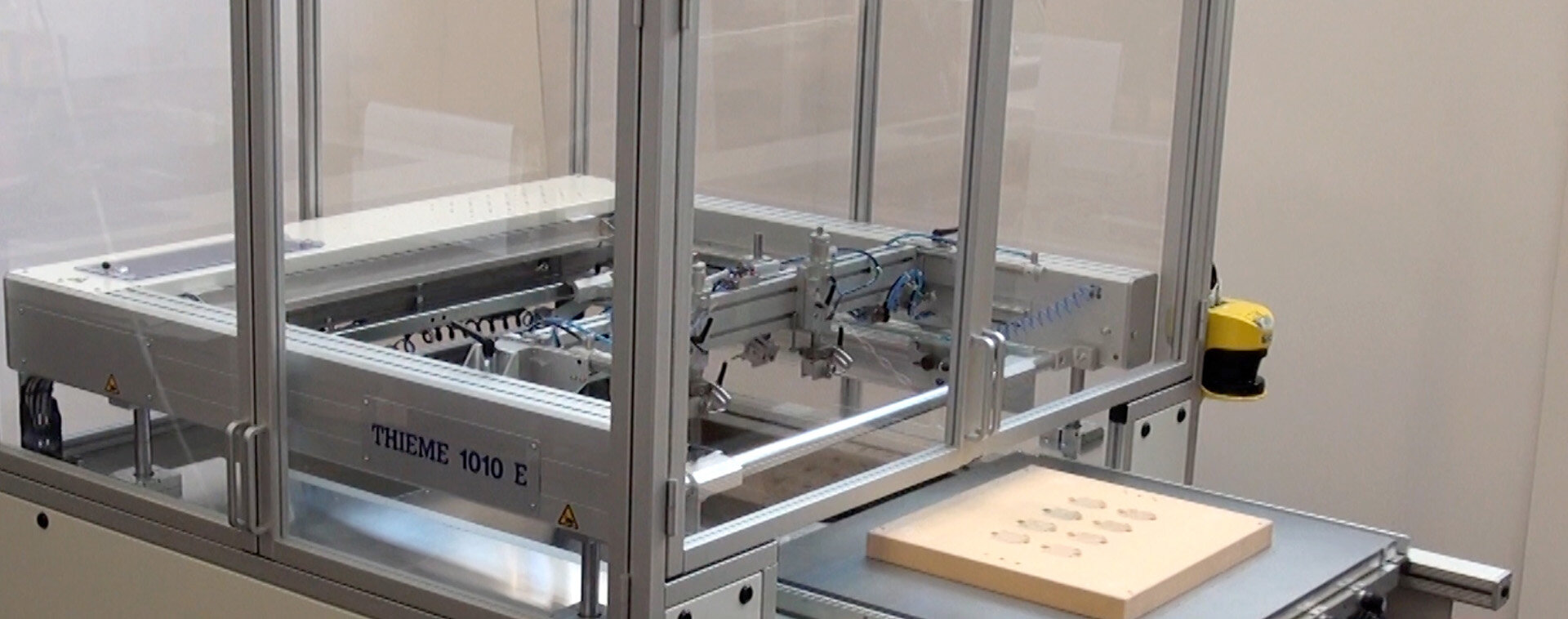

Semi-automatic shuttle table screen printing machine with moving print table for printing on rigid and flexible materials as used in electronic applications

SCREEN PRINTING SERIES

THIEME 1000 E

Semi-automatic shuttle table screen printing machine with moving print table for printing on rigid and flexible materials as used in electronic applications.

- High precision screen printing and easy operation on the highest technological level, max. adjustment to the print requirement

- Compact machine design

- The whole machine concept allows short set-up times and economic handling

- Available with THIEME CleanPrint

- The anti-drip feature provides perfect print quality and works well with translucent ink applications

- Precise printing results with optional THIEME screen compensation system

- The basic machine can be customized on request

Technical data

| Type of machine | 1010 E | 1020 E |

|---|---|---|

| Print size [mm] | 550x750 | 750x1050 |

| Sheet size max. [mm] | 570x770 | 770x1070 |

| Frame size [mm] | 1000x1100 | 1200x1400 |

| Table - External dimensions [mm] | 800x1100 | 1000x1300 |

| Vacuum field size [mm] | 525x735 | 720x1020 |

| Weight [kg] | 1200 | 1300 |

| Max. range of substrate thickness [mm] | 20 | |

| Table fine tuning X-X-Y [mm] | +/- 10 | |

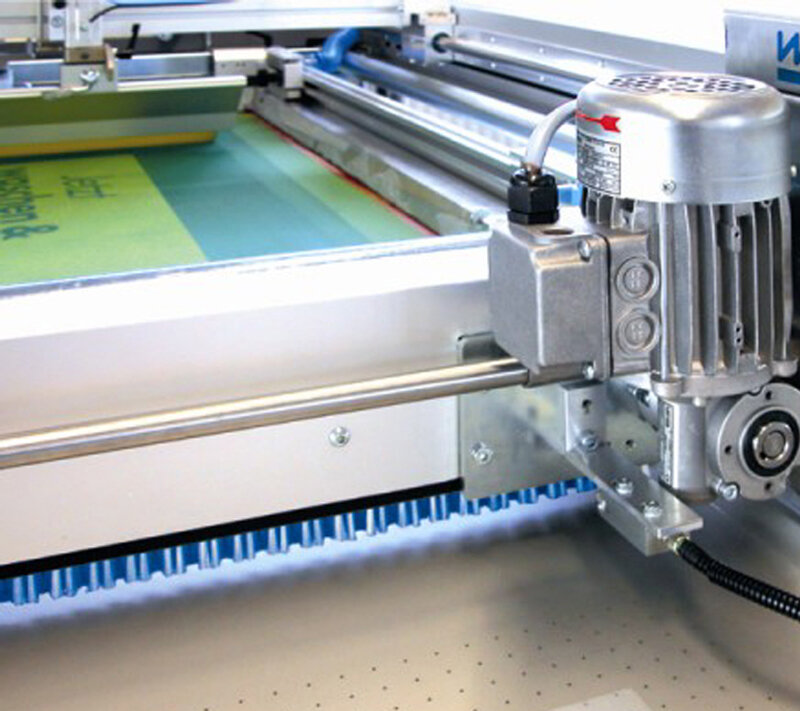

| Squeegee speed [m/sec] | 0,05-0,6 0,15-1,0 |

|

| Power supply [V] | 400/230 | |

| Circuit connection [kW] | 3,4 | |

| Consumption [A/V] | 12/400 | |

| Print speed on request. All technical information are not binding and subject to change. |

||

Why THIEME 1000 E?

- Customer-specific substrate positioning guides

- High reproducibility of + / - 50 μm

- Precise and fast make ready using the film set-up system

- High-precision table adjustment unit

- Low depreciation

- Thieme quality „Made in Germany“

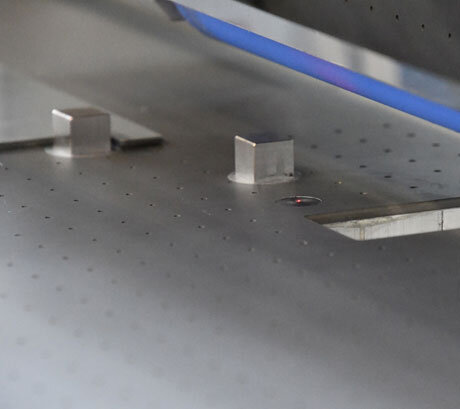

- Reinforced shuttle print table with 12 mm thick aluminum print surface

Specifics

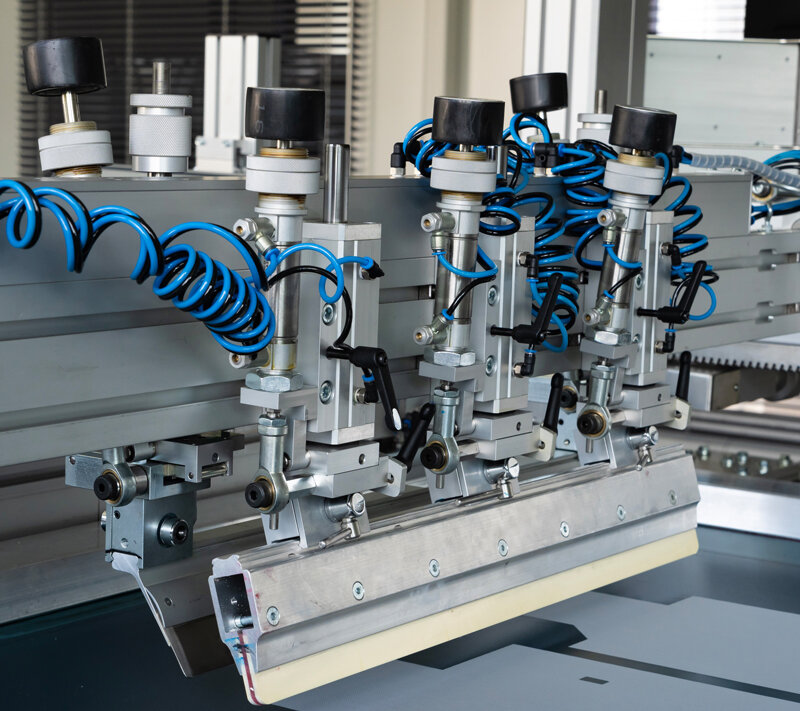

- Precise screen alignment by pneumatic 3-point system

- Modern touchscreen panel for user-friendly operation

- Pneumatic screen frame release

- Adaptation of the basic machine to the customer’s specific requirements

- Absolute precision thanks to optional screen tension compensation device

- Anti-drip squeegee system (optional)

- Automated Clean Print unit (optional)

Example options

Fields of application

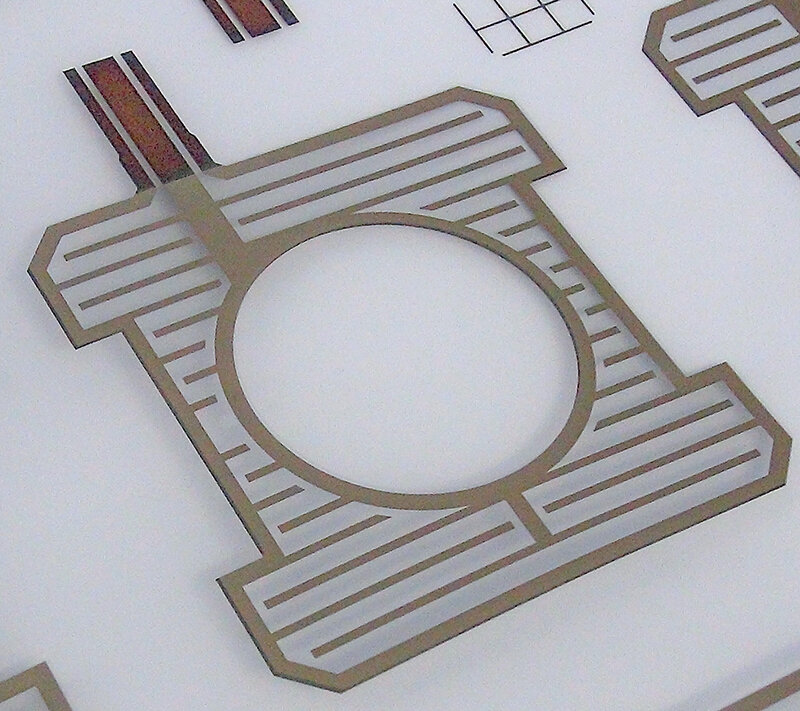

The application opportunities of functional printing processes know no bounds and something new is being added every day: for example, the production of antennas, membrane keypads or strip conductors.

More ...

We support our customers in the development of new processes by providing process entry solutions ("Lab-to-Fab"), which we test in our own Technology Center. We also perform feasibility studies.

If you had only know that ...

Customers are constantly bringing their special ideas to Thieme. Many special customized machines have already been developed due to the challenges posed by unusual printed fabrics or special materials.

More ...