Printing automotive glass with on-the-fly changeover

Published at 13.01.2020

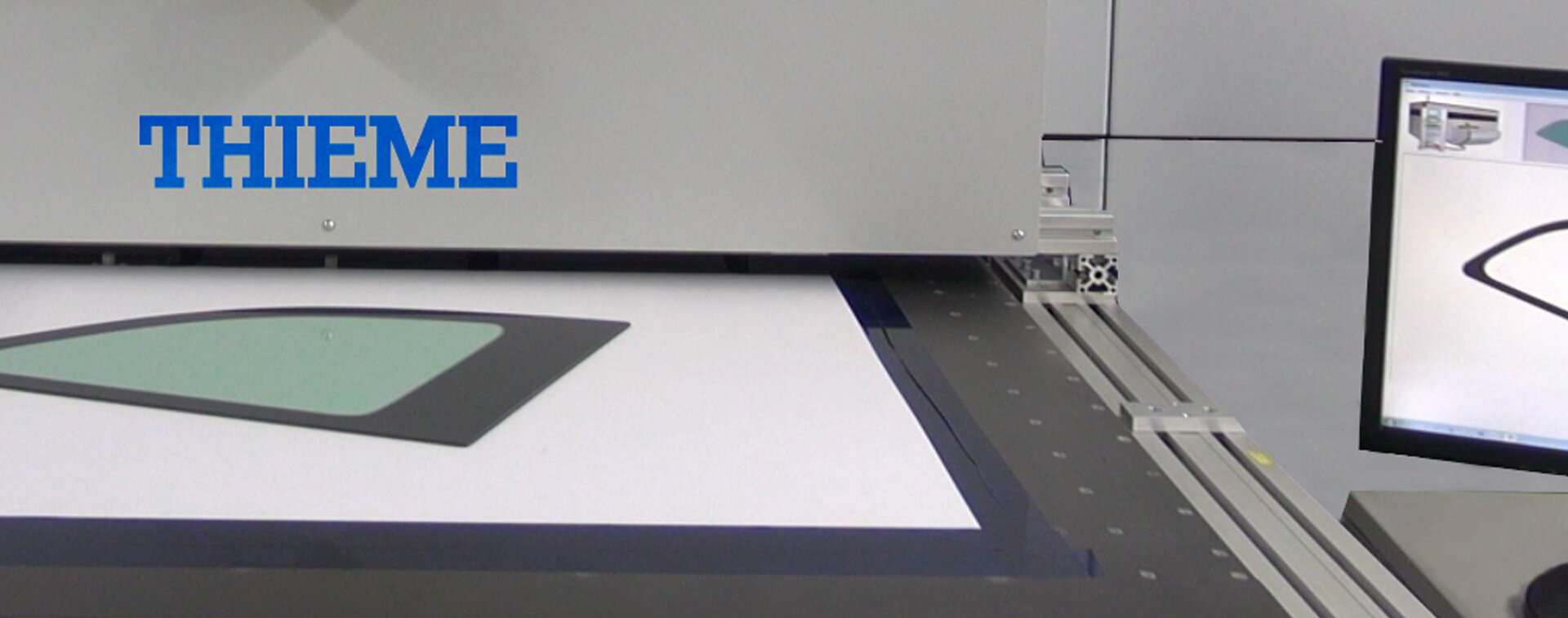

An innovation from THIEME for the digital printing of automotive glass: Thanks to automatic registration recognition system, the printing of various parts while keeping set-up times to a minimum.

The registration recognition system uses an optical scanner to switch between different automotive glass sizes and formats on the fly while keeping set-up times to two minutes or less. The glass position is automatically determined when the glass is placed on the transport system. The positional data is then sent to the machine control system. X, Y and rotational positions are accurately detected within ± 0.1 mm. By the time the glass reaches the printing station, its registration position has already been written to the RIP file, and the printing process can begin straight away without requiring any further mechanical adjustment.

The fully enclosed digital printing system comes in two versions: The THIEME PW260 is equipped with a highly productive page wide printing shuttle with 24 printheads, while the THIEME SR450 operates in step-and-repeat mode and so can print large-format pieces up to 1700 mm in size. Both machines also feature a multi-pass print mode that offers maximum print quality with minimum cycle times and, with a resolution of 800 x 800 dpi, can reproduce very finely detailed prints. The machines also come standard with a fully automatic printhead cleaning system to maintain consistent print quality. The printing systems are easy and ergonomically friendly to operate from a Siemens control terminal.

“Our new digital printing system, when combined with our proven glass transport systems, allows automated high-volume production processes for printing automotive glass,” explains Christian Schweickert, Thieme Sales. “The automatic registration recognition system significantly reduces set-up times, thereby increasing system throughput.”